Cov hauv qab no yog ua tiav cov txheej txheem tsim los ntawm SMT (nto mount thev naus laus zis) mus rau DIP (dual in-line pob), mus rau AI nrhiav pom thiab ASSY (lub rooj sib txoos), nrog rau cov neeg ua haujlwm muab kev taw qhia thoob plaws hauv cov txheej txheem. Cov txheej txheem no suav nrog cov kev sib txuas tseem ceeb hauv kev tsim hluav taws xob kom ntseeg tau tias kev tsim khoom zoo thiab ua haujlwm tau zoo.

Ua tiav cov txheej txheem tsim khoom los ntawm SMT → DIP → AI tshuaj xyuas → ASSY

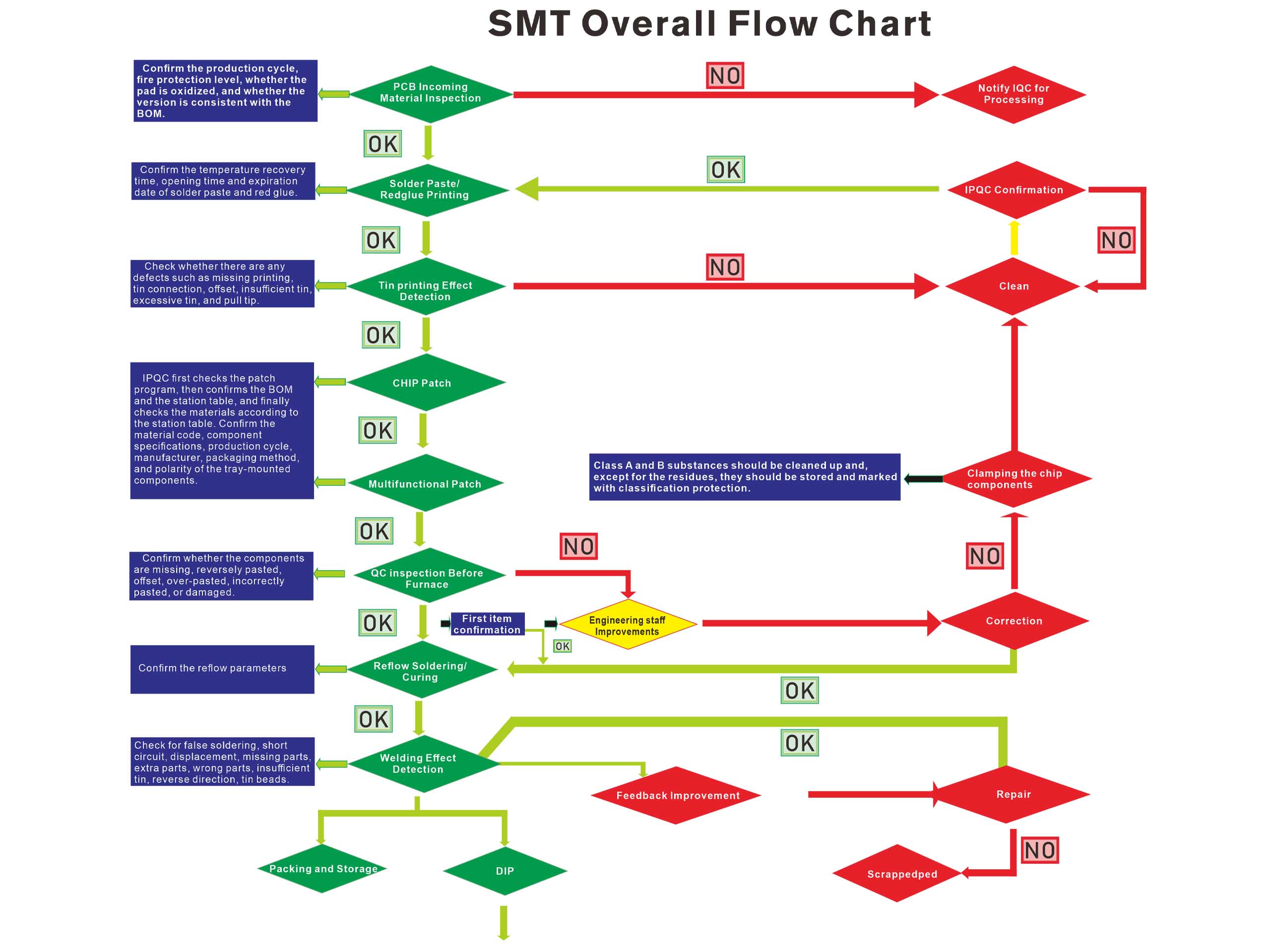

1. SMT (nto mount technology)

SMT yog cov txheej txheem tseem ceeb ntawm kev tsim hluav taws xob, feem ntau yog siv los txhim kho qhov chaw mount (SMD) ntawm PCB.

(1) Solder paste luam ntawv

Khoom siv: solder paste tshuab luam ntawv.

Cov kauj ruam:

Txhim kho PCB ntawm lub tshuab luam ntawv ua haujlwm.

Sau cov ntaub nplaum kom raug rau ntawm cov ntaub qhwv ntawm PCB los ntawm cov hlau mesh.

Xyuas qhov zoo ntawm solder paste printing kom paub meej tias tsis muaj offset, tsis muaj luam ntawv lossis overprinting.

Cov ntsiab lus tseem ceeb:

Lub viscosity thiab thickness ntawm cov tshuaj txhuam hniav yuav tsum ua tau raws li qhov yuav tsum tau ua.

Cov hlau mesh yuav tsum tau ntxuav tsis tu ncua kom tsis txhob txhaws.

(2) Qhov chaw tso khoom

Cov Khoom Siv: Xaiv thiab Muab Tshuab.

Cov kauj ruam:

Load SMD Cheebtsam rau hauv feeder ntawm SMD tshuab.

Lub tshuab SMD khaws cov khoom los ntawm lub nozzle thiab muab tso rau hauv qhov chaw teev tseg ntawm PCB raws li qhov kev zov me nyuam.

Txheeb xyuas qhov tseeb ntawm qhov tso kawm kom paub tseeb tias tsis muaj qhov offset, qhov tsis ncaj ncees lawm lossis qhov ploj lawm.

Cov ntsiab lus tseem ceeb:

Lub polarity thiab kev taw qhia ntawm cov khoom yuav tsum yog.

Lub nozzle ntawm lub tshuab SMD yuav tsum tau khaws cia tsis tu ncua kom tsis txhob muaj kev puas tsuaj rau cov khoom.

(3) Reflow soldering

Khoom siv: Reflow soldering rauv.

Cov kauj ruam:

Xa lub mounted PCB rau hauv reflow soldering rauv.

Tom qab plaub theem ntawm preheating, qhov kub thiab txias, reflow thiab txias, lub solder paste yog melted thiab ib tug txhim khu kev qha solder sib koom ua ke yog tsim.

Txheeb xyuas qhov zoo ntawm cov hlau nplaum kom paub tseeb tias tsis muaj qhov tsis xws li cov pob qij txha txias, kev sib txuas los yog qhov ntxa.

Cov ntsiab lus tseem ceeb:

Qhov kub nkhaus ntawm reflow soldering yuav tsum tau optimized raws li cov yam ntxwv ntawm cov tshuaj txhuam thiab cov khoom.

Calibrate lub cub tawg kub tsis tu ncua kom ruaj khov vuam zoo.

(4) AOI tshuaj xyuas (tsis siv neeg kho qhov muag)

Khoom siv: Tsis siv neeg kho qhov muag ntsuas ntsuas (AOI).

Cov kauj ruam:

Optically scan lub soldered PCB kom paub qhov zoo ntawm cov pob qij txha thiab cov khoom mounting raug.

Sau thiab txheeb xyuas qhov tsis xws luag thiab tawm tswv yim rau cov txheej txheem dhau los rau kev hloov kho.

Cov ntsiab lus tseem ceeb:

Qhov kev pab cuam AOI yuav tsum tau ua kom zoo raws li PCB tsim.

Calibrate cov cuab yeej tsis tu ncua kom paub tseeb tias qhov tseeb.

2. DIP (dual in-line pob) txheej txheem

Cov txheej txheem DIP feem ntau yog siv los nruab los ntawm lub qhov (THT) thiab feem ntau yog siv ua ke nrog cov txheej txheem SMT.

(1) Insertion

Khoom siv: phau ntawv los yog tsis siv neeg ntxig tshuab.

Cov kauj ruam:

Ntxig cov khoom siv los ntawm lub qhov rau hauv qhov chaw ntawm PCB.

Txheeb xyuas qhov tseeb thiab ruaj khov ntawm cov khoom siv ntxig.

Cov ntsiab lus tseem ceeb:

Cov pins ntawm cov khoom yuav tsum tau muab txiav kom ntev li ntev tau.

Xyuas kom meej tias cov khoom polarity yog lawm.

(2) Wave soldering

Khoom siv: yoj soldering rauv.

Cov kauj ruam:

Muab lub plug-in PCB tso rau hauv lub yoj soldering rauv.

solder lub tivthaiv pins rau PCB pads los ntawm yoj soldering.

Txheeb xyuas qhov zoo ntawm soldering kom paub tseeb tias tsis muaj cov pob qij txha txias, txuas los yog cov pob qij txha tawg.

Cov ntsiab lus tseem ceeb:

Qhov kub thiab ceev ntawm yoj soldering yuav tsum tau optimized raws li cov yam ntxwv ntawm PCB thiab cov khoom.

Ntxuav lub tshuab ntxhua khaub ncaws tsis tu ncua kom tsis txhob muaj impurities los ntawm kev cuam tshuam qhov zoo ntawm soldering.

(3) Phau ntawv soldering

Manually kho lub PCB tom qab yoj soldering los kho qhov tsis xws luag (xws li txias solder pob qij txha thiab bridging).

Siv cov hlau nplaum los yog phom cua kub rau hauv zos soldering.

3. AI detection (kev txawj ntse txawj ntse)

Kev tshawb nrhiav AI yog siv los txhim kho qhov ua tau zoo thiab qhov tseeb ntawm kev tshawb pom zoo.

(1) AI pom kev pom

Khoom siv: AI pom pom qhov system.

Cov kauj ruam:

Nthuav cov duab siab ntawm PCB.

Txheeb xyuas cov duab los ntawm AI algorithms txhawm rau txheeb xyuas qhov tsis xws luag, kev tiv thaiv kev tiv thaiv thiab lwm yam teeb meem.

Tsim ib daim ntawv ntsuam xyuas thiab pub nws rov qab rau cov txheej txheem tsim khoom.

Cov ntsiab lus tseem ceeb:

Tus qauv AI yuav tsum tau kawm thiab ua kom zoo raws li cov ntaub ntawv tsim tawm tiag.

Hloov kho AI algorithm tsis tu ncua txhawm rau txhim kho kev tshawb pom qhov tseeb.

(2) Kev sim ua haujlwm

Khoom siv: Cov cuab yeej siv tshuab ntsuas (ATE).

Cov kauj ruam:

Ua kev ntsuam xyuas hluav taws xob ua haujlwm ntawm PCB kom ntseeg tau tias kev ua haujlwm ib txwm muaj.

Sau cov txiaj ntsig kev xeem thiab txheeb xyuas qhov ua rau ntawm cov khoom puas.

Cov ntsiab lus tseem ceeb:

Cov txheej txheem xeem yuav tsum tau tsim raws li cov yam ntxwv ntawm cov khoom.

Tsis tu ncua calibrate cov cuab yeej xeem kom paub meej qhov kev xeem.

4. ASSY txheej txheem

ASSY yog cov txheej txheem ntawm kev sib dhos PCB thiab lwm yam khoom siv rau hauv cov khoom tiav.

(1) Mechanical sib dhos

Cov kauj ruam:

Nruab lub PCB rau hauv lub vaj tsev lossis lub bracket.

Txuas lwm yam khoom xws li cables, nyees khawm, thiab tso saib cov ntxaij vab tshaus.

Cov ntsiab lus tseem ceeb:

Xyuas kom muaj kev sib dhos kom raug kom tsis txhob muaj kev puas tsuaj rau PCB lossis lwm yam khoom.

Siv cov cuab yeej tiv thaiv zoo li qub los tiv thaiv kev puas tsuaj zoo li qub.

(2) Software hlawv

Cov kauj ruam:

Hlawv lub firmware lossis software rau hauv lub cim xeeb ntawm PCB.

Tshawb xyuas cov txiaj ntsig hlawv kom paub tseeb tias cov software khiav ib txwm.

Cov ntsiab lus tseem ceeb:

Qhov kev pab cuam hlawv yuav tsum phim lub hardware version.

Xyuas kom meej tias qhov chaw kub kub ruaj khov kom tsis txhob muaj kev cuam tshuam.

(3) Tag nrho cov tshuab kuaj

Cov kauj ruam:

Ua cov kev ntsuam xyuas ua haujlwm ntawm cov khoom sib dhos.

Xyuas qhov zoo li, kev ua tau zoo thiab kev ntseeg tau.

Cov ntsiab lus tseem ceeb:

Cov khoom xeem yuav tsum npog tag nrho cov haujlwm.

Sau cov ntaub ntawv xeem thiab tsim cov ntawv ceeb toom zoo.

(4) Ntim thiab xa khoom

Cov kauj ruam:

Anti-static ntim ntawm cov khoom tsim nyog.

Sau npe, ntim thiab npaj rau kev xa khoom.

Cov ntsiab lus tseem ceeb:

Ntim yuav tsum ua tau raws li kev thauj mus los thiab kev cia khoom.

Sau cov ntaub ntawv shipping kom yooj yim traceability.

5. Cov ntsiab lus tseem ceeb

Environmental tswj:

Tiv thaiv kom tsis txhob muaj hluav taws xob zoo li qub thiab siv cov khoom siv thiab cov cuab yeej tiv thaiv zoo li qub.

Cov cuab yeej tu:

Tsis tu ncua tswj thiab calibrate cov cuab yeej xws li tshuab luam ntawv, tso tshuab, reflow ncu, yoj soldering ncu, thiab lwm yam.

Txheej txheem optimization:

Optimize txheej txheem tsis raws li qhov tseeb ntau lawm tej yam kev mob.

Kev tswj kom zoo:

Txhua tus txheej txheem yuav tsum tau soj ntsuam nruj nruj kom ntseeg tau tias muaj txiaj ntsig.